Have you ever experienced the frustration of a twisted metal axle? If you’ve spent time working on vehicles or machinery, chances are you’ve encountered this issue. A twisted metal axle can lead to poor performance and costly repairs if not addressed promptly. Whether it’s from heavy loads, rough terrain, or just plain wear and tear, knowing how to identify and repair a twisted metal axle is essential for any DIY enthusiast or professional mechanic.

In this blog post, we’ll explore what exactly a twisted metal axle is and dive into the common causes behind its deformation. We will also provide you with practical steps to fix it yourself along with the tools you’ll need. Plus, we’ll share some crucial safety measures and tips for maintaining your axles in optimal condition. Let’s get started on keeping your vehicle running smoothly!

What is a Twisted Metal Axle?

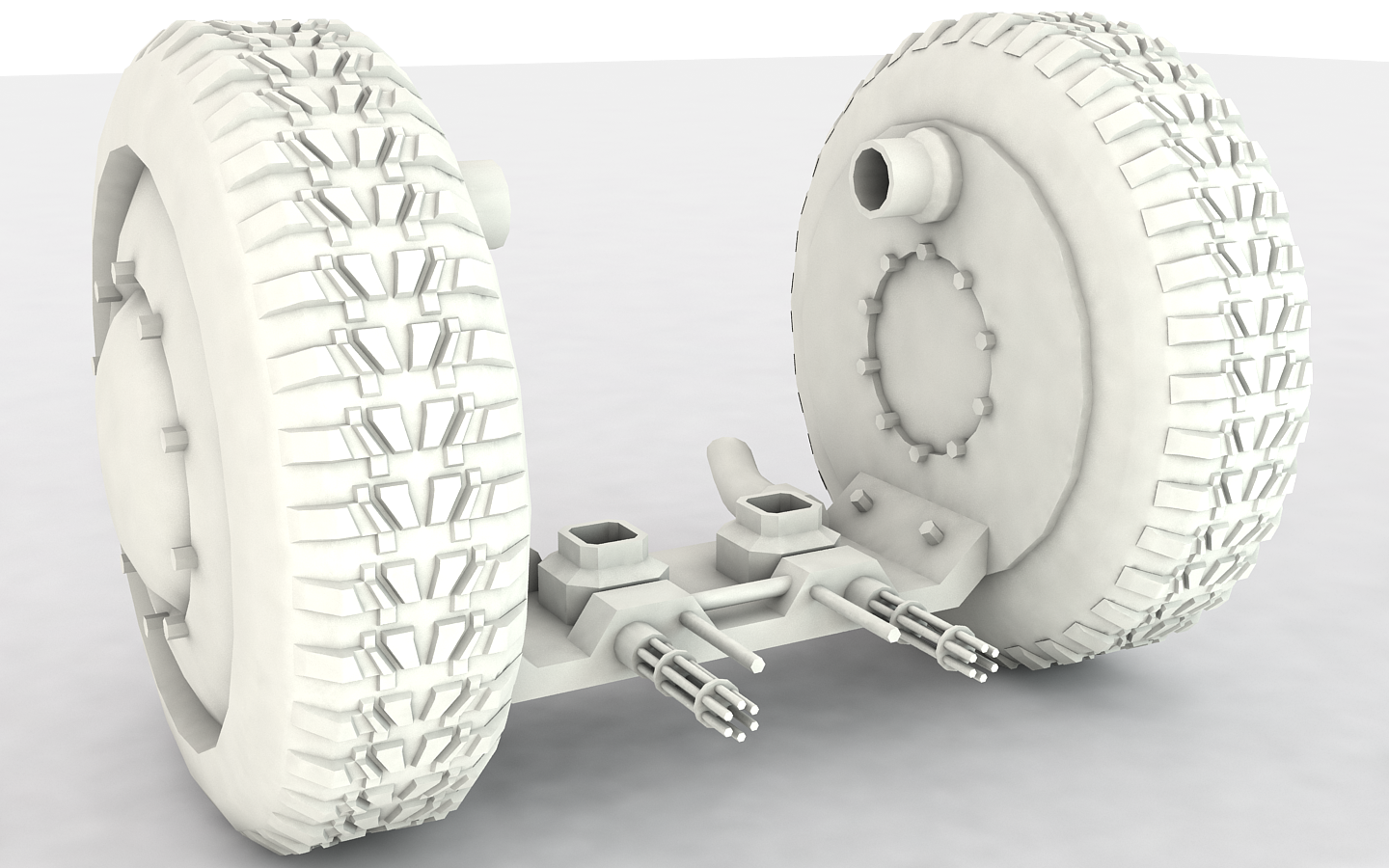

A twisted metal axle refers to an axle that has become distorted or bent due to various stress factors. This essential component connects the wheels of a vehicle, allowing for smooth rotation and weight distribution.

When an axle twists, it can compromise the alignment and stability of your vehicle. You might notice uneven tire wear or difficulty steering as symptoms of this issue. The damage often occurs in high-stress situations like off-roading, carrying heavy loads, or hitting bumps at high speeds.

Twisted axles not only affect performance but can also pose safety risks. Understanding what constitutes a twisted metal axle is crucial for anyone looking to maintain their vehicle’s integrity and reliability on the road or trail.

Common Causes of Twisted Metal Axles

Twisted metal axles can result from various factors. One of the most common causes is excessive load on the vehicle. When too much weight is placed on an axle, it struggles to bear the burden, leading to deformation.

Another frequent culprit is rough terrain. Driving over bumpy roads or uneven surfaces puts significant stress on suspension components and axles alike.

Additionally, collisions play a major role in twisting axles. A sudden impact can cause immediate damage that may not be visually apparent at first glance.

Poor maintenance practices also contribute to this issue. Neglecting regular inspections can allow small problems to escalate into serious structural failures.

Manufacturing defects may occasionally occur during production, resulting in weakened points that are prone to twisting under normal use conditions.

Steps to Repair a Twisted Metal Axel

Start by assessing the damage to your twisted metal axle. A thorough inspection will help you determine how severe the twist is and whether it can be repaired or needs replacement.

Next, securely position the axle in a sturdy vice or clamp. This step prevents any movement while you work on straightening it.

Use heat to soften the metal slightly. A propane torch works well for this; apply heat evenly along the twisted section without overheating.

Once heated, use a pipe wrench or large pliers to gently twist and straighten the axle back into place. Take your time here—too much force can cause further damage.

After achieving alignment, allow it to cool gradually before testing its strength through careful pressure application. If satisfied with repairs, clean off any debris and reapply protective coatings where necessary.

Tools and Materials Needed for Repair

To tackle a twisted metal axel, having the right tools is essential. A high-quality jack stands out as a must-have for safely lifting your vehicle. This ensures you have access to the axle without compromising safety.

Next on the list are wrenches and sockets. These will help in loosening and tightening bolts efficiently during the repair process. It’s wise to invest in metric sizes as well since many vehicles use them.

A heat source can also be beneficial if you’re dealing with stubborn components that need extra persuasion. A propane torch is often sufficient for heating metal parts before making adjustments.

Don’t forget about protective gear! Safety goggles and gloves protect against flying debris or sharp edges while working on your axle.

Keep some penetrating oil handy; it works wonders when loosening rusted bolts or fittings that may hinder your repair efforts.

Precautions and Safety Measures

When repairing a twisted metal axle, safety should always come first. Wear protective gear such as gloves, goggles, and steel-toed boots. This simple step can save you from serious injuries.

Ensure your workspace is well-lit and organized. A clutter-free area helps prevent accidents while you’re focused on the task at hand.

Always use appropriate tools for each job to avoid damage or injury. Mismatched tools can lead to mishaps that could worsen the situation.

If you’re working under a vehicle, make sure it’s securely lifted using jack stands. Never rely solely on a hydraulic jack; it’s crucial to have added support.

Be aware of sharp edges and hot surfaces during repairs. Metal can become extremely hot if exposed to welding or cutting processes.

Taking these precautions will help ensure not only your safety but also the success of your repair efforts.

Tips for Maintaining Your Axle to Prevent Twists

Regular inspections are key to preventing axle twists. Check for signs of wear or damage frequently. Look closely at the alignment and any bending.

Proper lubrication also plays a critical role in maintaining your axle’s integrity. Regularly apply grease to moving parts, ensuring everything operates smoothly.

Be mindful of load limits. Overloading your vehicle places unnecessary stress on the axle, increasing the risk of twisting.

Maintain tire pressure within recommended ranges too. Uneven tires can cause undue strain during turns and bumps.

Keep an eye on suspension components as they support your axle’s weight distribution. Ensure these elements are in good condition to help prevent future issues with twisting.

Taking proactive steps today can save you significant time and money later on repairs that could have been avoided.

Conclusion

Repairing a twisted metal axle can seem daunting, but with the right knowledge and tools, it becomes manageable. Understanding what causes these twists helps in both repair and prevention. By following systematic steps for fixing your axle, you can ensure safe driving conditions.

Always remember to take proper safety precautions while working on vehicle parts. Regular maintenance is key to reducing the chances of an axle twisting again in the future. Keeping your vehicle well-maintained not only enhances performance but also extends its lifespan.

Invest time in learning about your vehicle’s components and build good habits that will benefit you long term. With diligence and care, you can keep your axles—and ultimately your entire vehicle—in top shape.